The Labadis system

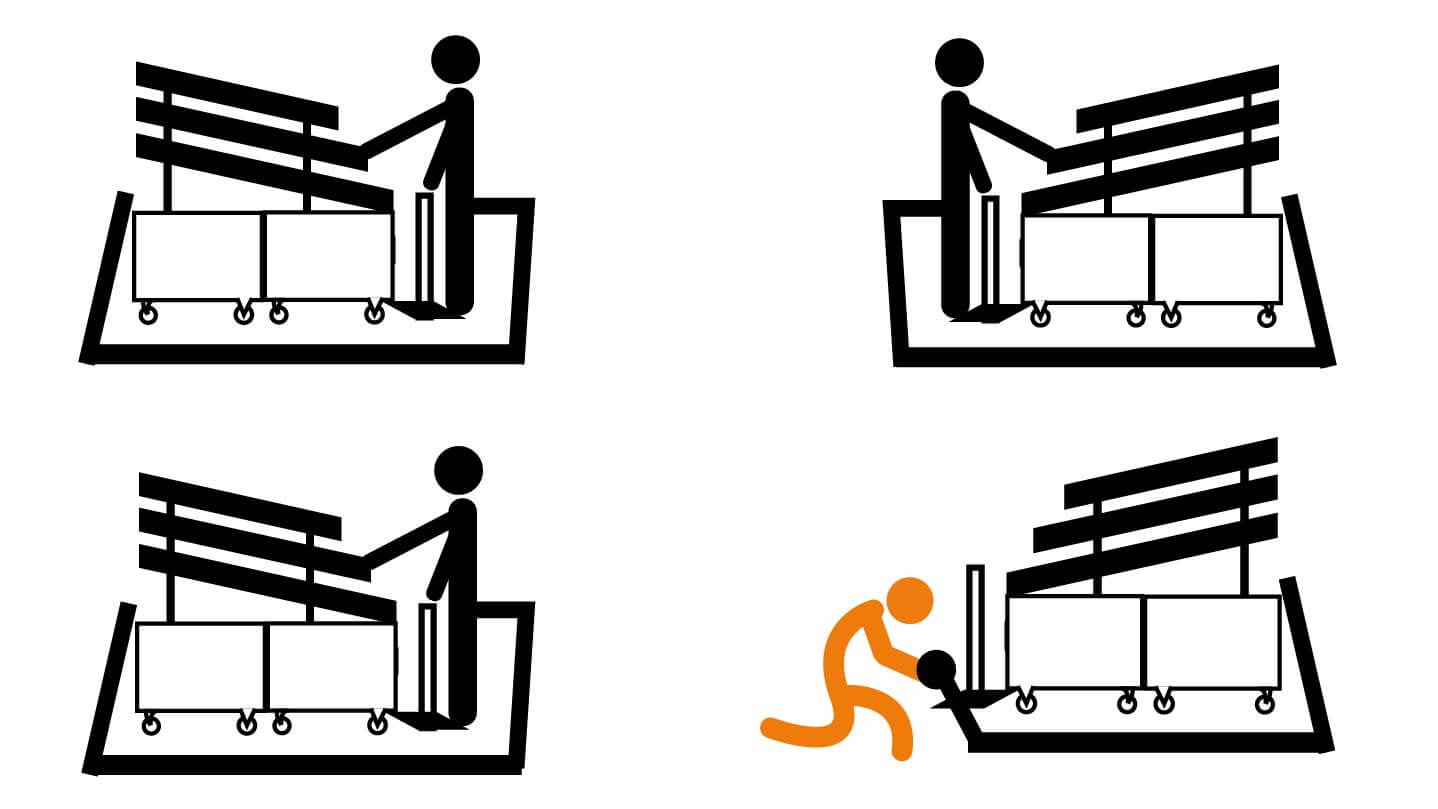

Movements

Improvement of the workstation

On the workstation, the flow is characterized by gestures and movements that are costly in terms of ergonomics, productivity and surface area. We seek to limit or even eliminate them.

The workstation is composed of 3 elements:

- The work support: a stand adapted to the part

- The tools: adapted to the task

- The supplies: containers or trolleys adapted to the parts to be transported and to the diversity of the components.

- 5S: Make the workstation obvious to keep tidy and clean with intuitive and visual solutions.

- Hoshin: Increase the productivity of a workstation, of a process by reducing all non-added value actions.

- GRP: Problem Solving Group; Find the root cause of a waste or problem in order to remove it permanently.

Before

After

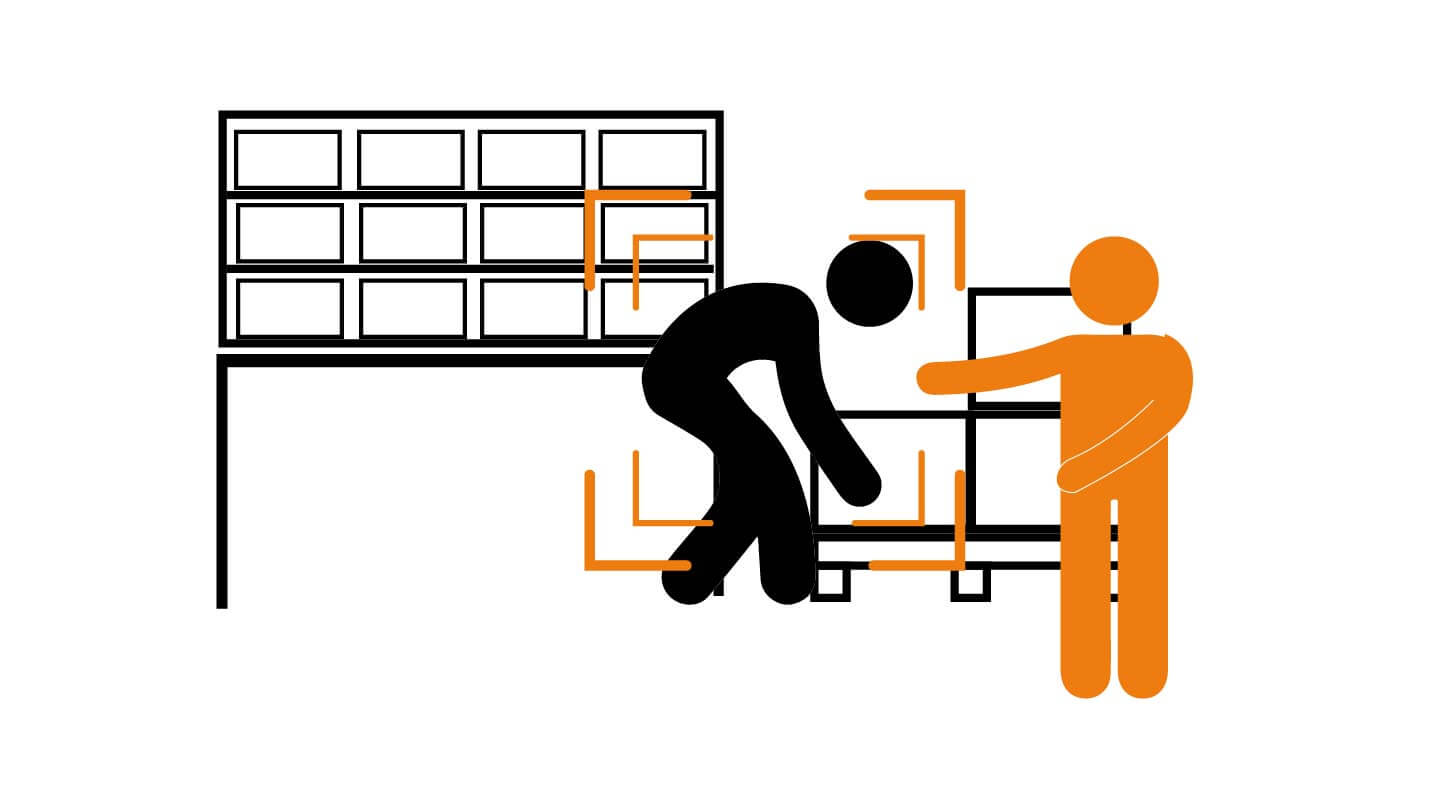

Improvement of the line

Once each station has been optimized, the balancing of the stations between them improves the productivity of the line according to the requested Takt Time. This time can vary to adapt to customer demand.

The transfer of the product from one station to another represents additional movements that will be limited by the configuration of the line and the work in “one piece at a time”.

The standardization and modularity of the Labadis system makes the design and evolution of production means simple and fast for the methods teams.

- SMED: 5S of tools + Hoshin of operating modes to reduce series change time and batch size

- TPM: 5S of machines + reliability GRP + Hoshin of maintenance activities in order to have reliable and productive machines

- Steward method: Definition of packaging, line side delivery, supply mode at the station

- Process Design: Design of manual or automated lines

Before

After

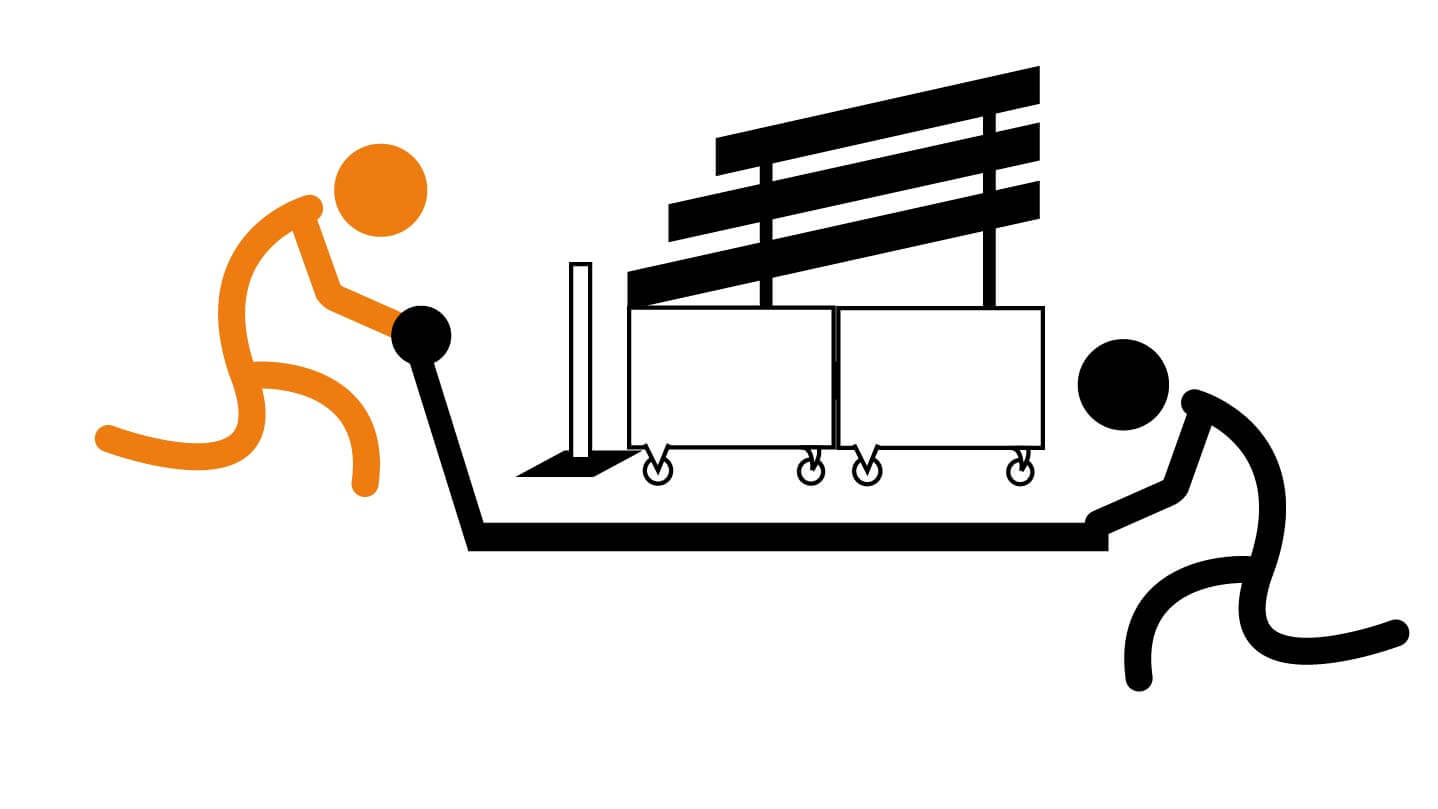

Transfers

Transfers

If we look at the factory from the sky, we can see multiple movements for parts, information, waste, non-quality, raw material…And for all these movements, we must recover, find the destination, deliver.

Productivity:

To reduce movements, Labadis proposes to mutualize all transfers. This is made possible by the standardization and compatibility of all the Rollis trolleys in the Labadis system.

To increase the efficiency of delivery and picking operations, Labadis proposes to structure departures and arrivals. How can this be done? With line side delivery, flat storage and kanban solutions that are all compatible.

Surface:

The Labadis system allows a compact and efficient transfer of flows thus reducing the surface dedicated to handling and movements.

Safety:

The telescopic system ensures braking in less than one meter: handling becomes a safe and serene activity.

Energy:

The Labadis system reduces energy consumption related to transfers.

The Rollis system transfers products on wheels pulled by a light locomotive (250 kg) where forklifts (5 times heavier than their load) move pallets.

The Rollis system allows storage on the ground, whereas pallets need to be stored at height, which requires large energy-consuming machines.

Automation:

The Labadis system simplifies transfers and facilitates automatizaton. The small Labadis train is perfectly adapted to AGVs.

Digitalization 4.0:

The Labadis system adapts to the digitalization of the industry.

By making the flow more compact and more frequent, it facilitates the collection of information, whether by RFID or by scanning datamatrix codes. This avoids simultaneous responses from many IOTs and allows for the simplification of algorithms.

The 4.0 factory that is becoming automated will find flow components in the Labadis system. The Rollis with telescopic towbar eliminates the risk of accidents.

Before

After

Reconditioning & Packaging

Wheels reconditioning

Delivery of trolley wheels

External logistics loop

The Labadis system is designed to improve the entire production flow, even if the customer and supplier are in distant factories.

With the Labadis system, a truck with a 13.5 m floor can be unloaded in less than 10 minutes. The rows of 22 Rollis are taken out in one go. The Rollis trucks are then put directly into the Flat Storage or unloaded into the dynamic racks. Receiving work becomes a regular and productive activity.

- Mutualize all the flows (raw materials, products in process, waste …) in the plant. Size and organize the train work.

- Manage the supply of workstations by internal and external customer demand

- Standardize your flow logic with your suppliers and customers

Before

After

Stocks

Stocks

The stock ensures delivery to the customer by compensating for various problems or constraints.

The storage in Rollis® trolley of large volume or high consumption parts allows to have the whole stock of a part, in a single width of 400 mm. No more searching in the pallet rack and maneuvering the forks, the part is always in the same place.

The time required to place and search for parts is reduced from an average of 4 minutes to 15 seconds. The FIFO (First In First Out) is automatically respected.

A part that is close to being out of stock is visible to the user (the supplier) as well as the stock manager. This results in a better reactivity and a reduction of supply shortages.

Each reference has a unique location sized according to the supplier’s constraints, so the storage density is maximum and the surface area optimized.

Flat storage reduces storage space by optimizing aisles.

To improve your stocks, we can offer you the following workshops

- Increase the speed of stock response following customer demand.

- Improve safety by eliminating forklifts

Before

After

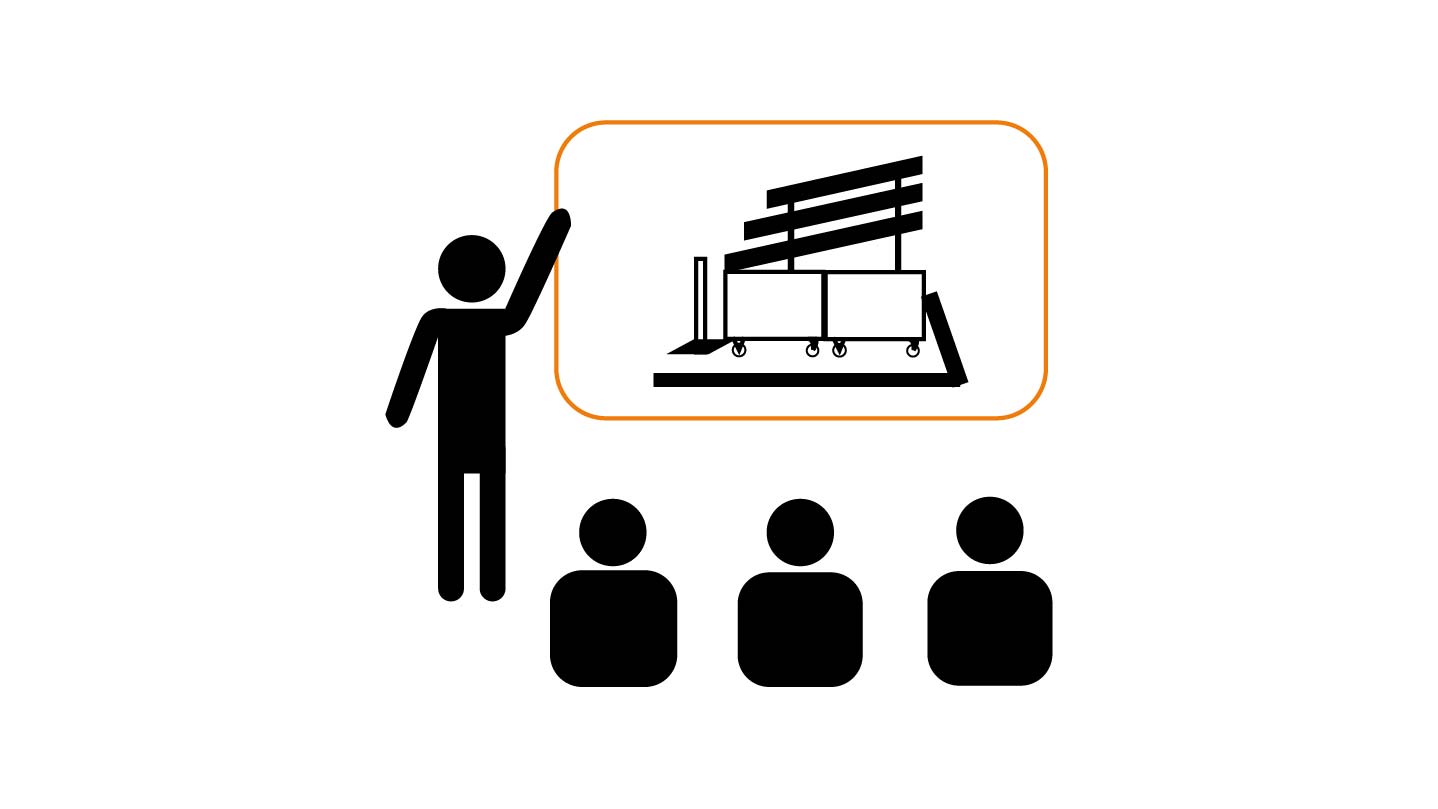

Project stages

Our engineers are at your disposal to study, configure and set up an optimized organization with you.

Exchange

Diagnosis

Proposal

Intervention

Deployment